Induction Heating

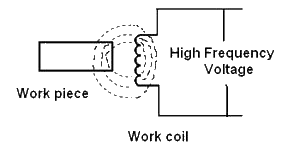

Induction heating is the process in which heat is produced inside a conducting material (magnetic & non-magnetic), according to the Faraday’s law of electromagnetic induction, whenever a conductor is placed in a varying magnetic flux, the EMF (voltage) is induced in that conductor. The work piece of metal that is to be heated is placed within the work coil, high frequency voltage is applied to the work coil this set up an alternating flux or field. The workpiece cuts the flux and voltage is induced in it, which is called eddy current, this eddy current passes through the workpiece resulting in heat.

The work works as primary coil of the transformer, while the workpiece (which is heated) works as a secondary of the transformer. With this method the heat is produced in steel 50 times faster than heat can be transferred into the metals in the furnace and resulting temperature is more uniform throughout, since higher temperature is used in induction welding. Non-magnetic materials are also heated through induction method.

Important Features of the Induction heating

- The heat is control near the surface of the work coil.

- Very high heating rate can be obtained.

- Skilled labours are not required of the operation.

- At working place there is no smoke and dust.

Applications of induction heating

There is some important application of the indication heating.

- Surface harding of steel

- Soldering

- Drying of paints

- Melting of costly materials.