Ultrasonic Waves

The frequencies which are beyond the limit of hearing are called ultrasonic. The ultrasonic waves are of frequencies above 20000Hz (20 KHz).

Features of Ultrasonic Waves

- They are highly energetic

- There speed of propagation depends upon their frequencies.

- They can be transmitted over long distance without any appreciable loss of energy.

- Intense ultrasonic radiation has disraptive effect on liquids by causing bubbles to be formed.

Applications of Ultrasonic Waves

Ultrasonic waves are used for the following purposes.

- Ultrasonic flaw detection.

- Cutting and matching of hard materials.

- Ultrasonic soldering and welding.

- Measurement of flow devices.

- Applications in medicine.

- Thermal effect.

- Ultrasonic as means of communication.

Principal of Pulsed Echo Ultrasonic Flaw Detector

Pulsed echo ultrasonic flaw detector works on the principle of reflected signal indication. The ultrasonic pulse uses high frequencies of 0.8 to 2.5 MHz for inspection of steel, Alluminium and Brass articles. But uses lower frequencies for inspection of plastic goods etc.

Generally, a single prob or transducer is used. This transducer first acts as a transmitter sending out a pulse of high frequency ultrasonic waves into the article to be inspected and then acts as a recivver to reciver the ultrasonic echo pulses reflected from the flaw and from the far end of the material. The recieved ultrasonic echo pulses are transformed by the transducer into the corresponding electric echo pulses of the same frequency. These are than amplified and displayed in the form a series of pulses on the screen of C.R.O. The first pulse corresponds to the transmitted pulse.

This followed by the pulse corresponding to flaw and lastly comes the pulse from the far end of the material. As shown in figure.

The distance of the echo pulse from the transmitted pulse gives the location of the flaw from the near end. Thus, the process of inspection is very simple.

Methodes to Generate Ultrasonic

Ultrasonic are generated by using oscillators namely.

- Piezo Electric Oscillator.

- Magneto Striction Oscillator.

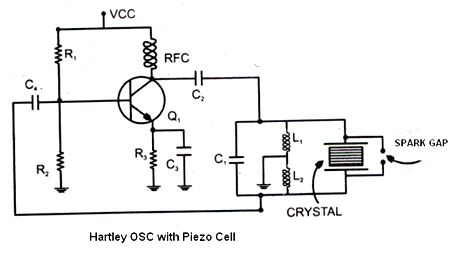

Piezo Electric OSC / Hartley OSC with piezo Cell

According to the piezo electric effect, when a (variable) mechanical force is applied across two opposite faces of the crystal cell, a potential difference is produce across it, when an alternating Current (AC) is applied across it terminals, the crystal cell start vibration at its natural frequency.

Piezo Electric OSC

If the frequency of the OSC is similar with the natural frequency of crystal, the vibration will be at large scale. This phenomenon of resonance is used for the generation of the ultrasonic waves.

The high frequency alternating voltage which is applied to the crystal cell is obtained by the Hartley OSC, as shown in the below figure. The piezo electric OSC is consist on a tune OSC circuit of a parallel L1 and C3, one end of this tune circuit is connected to the grid, the coil L1 tapped nearly at the center and connected to the cathode of the tube. The crystal is connected to in parallel with the capacitor C1 and grid capacitor (CG). The DC voltage is applied through radio frequency chock, this radio frequency chock prevent the DC voltage source from radio frequencies. The blocking Capacitor (CB) which prevent DC to pass through the tank circuit, the capacitance of the capacitor C2 is so adjusted that the frequency of OSC is equal the natural frequency of the Crystal cell, thus the ultrasonic waves are produce.

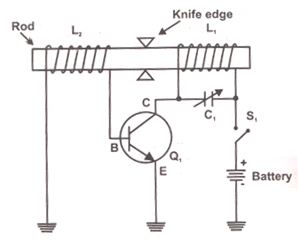

Magneto Striation OSC

If a bar or rod (tube) of pero magnetic material or nickel are change there length or start vibrate when they placed in strong varying magnetic field, which is parallel to the length of the bar. The iron bar or tube is fixed in the meddle and placed inside of the two coils L1 and L2, the exiting coil L1 from the inductance in tuned circuit by suitable, by adjusting of the variable capacitor C1, the high frequency current start flowing through the coils and producing varying magnetic field which produces a change in length of bar or tube due to which it start vibrating at its natural frequency.