CO2 Laser (The molecular gas laser)

The CO2 stands for carbon dioxide. In CO2 laser the laser light takes place within the molecules of carbon dioxide rather than within the atoms of a pure gas. Therefore CO2 gas laser is considered the type of molecular gas laser.

Importantly note that CO2 lasers use carbon dioxide as well as Helium & Nitrogen as its active medium.

Characteristics of CO2 lasers

The CO2 laser produces a far infrared beam at 10.6 microns. It can also operate with an output of 9.6 microns but this output is not much common. The beam divergence of the CO2 gas laser ranges from 1 to 10 milli radians. The beam width varies from 3mm for low power lasers up to 100mm for high powered lasers. The CO2 laser can be operated in either CW or Pulse mode commonly.

Continuous wave (CW) power output can ranges from few watts to over 15,000 watts. In pulsed mode peak power output can be in the millions of watts.

The operating frequency for CO2 laser is about 10% normally but theoretically it could be much higher.

Construction of CO2 gas laser

The CO2 gas laser can be constructed in the number of different configurations. In each configuration there is a specific manner in which the gas flows in the tube.

Five important configuration of CO2 laser constructions are

- Sealed tube design

- Coaxial flow design

- Fast axial flow design

- Transverse flow design

- TEA design

Sealed Tube design:

In this design the gas is sealed in the glass tube. This laser configuration can be pumped either with DC or RF excitation methods.

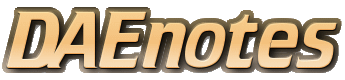

By diagram sealed tube design can be shown as:

If DC excitation is used with the sealed tube CO2 laser then it is much like constructed as He-Ne gas laser, however it is necessary to have an elaborate cooling system with the laser.

If RF (Radio frequency) excitation is used with sealed tube CO2 laser then construction can be shown as above. The figure shows that pumping power is provided an RF power supply. The energy is coupled to the laser using a matching transformer, designed for maximum power transfer. The output from RF supply is coupled to a number of electrodes that are space around the laser tube. The RF energy is absorbed with very little temperature rise.

Transverse Flow design

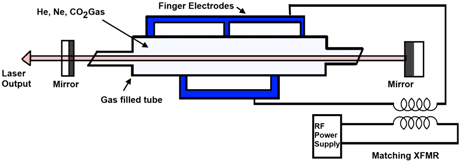

Transverse flow design of CO2 laser is:

Here the tangential blower circulates low pressure CO2 gas around the inside of the laser tube. Current flow through the tube is perpendicular to the movement of the gas. The optical cavity is perpendicular to both gas and current flow.

When the gas (moving at high speed) flows around the inside of the tube then it passes through the heat exchanger. This efficient method of cooling permits this type of laser to achieve higher power per unit length of the gas. The disadvantage of transverse flow design is the short and thick optical cavity. A cavity of this shape favors the multimode beams rather than TEM0,0 beam.

TEA design

The TEA stands for Transverse Excitation at atmospheric pressure. This design is considered the variation of the transverse flow design. With this design the gas that flows around the inside of the tube is maintained at near atmospheric pressure. This high density gas allows extremely high power outputs, however it is very difficult to maintain ionization it the gas when the gas is at high pressure.

Generally voltages required to maintain this type of operation are extremely high, that is why the TEA designed laser can only be operated in pulsed mode.

Remember that beam diameter for this type of laser varies from 5 to 10mm and the beam divergence is typically 1 to 2 millimeter also efficiency varies from 1 to 10%.

Function of CO2 Laser

The CO2 gas laser uses a mixture of Helium, Nitrogen and carbon dioxide as the active medium. In this mixture the helium and nitrogen work in concert with the CO2 to produce the desired lasing effect.

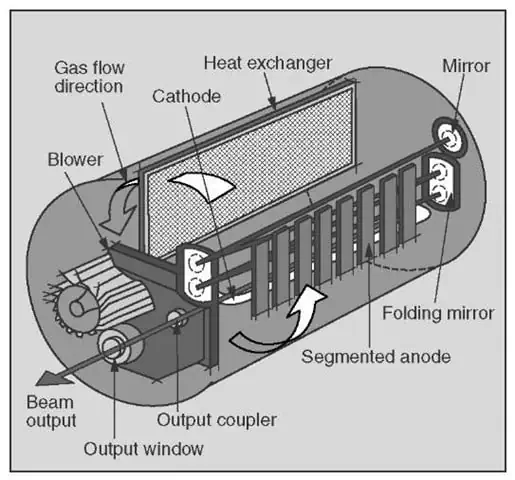

Here the Nitrogen gas acts as buffer gas, just like the Helium did in He-Ne laser. The Nitrogen gas absorbs the pumping energy from the current flow in the gas and transfer the energy through collisions to the CO2 molecule. Now when this CO2 molecule drops from an excited level to another level then lasing occurs. Energy level diagram for CO2 laser is as:

During the process shown, the lower lasing level must remain with a low population. Therefore the molecule must be removed from the lower lasing level as soon as it has emitted its photon. This can be done by cooling the gas. But most cooling systems can not cool the gas quick enough to keep the lower lasing level depopulated. Therefore the helium gas is used in CO2 lasers. When the helium gas enters the process then it removes energy from the CO2 molecule by atomic collision and so reducing the molecules to the lower energy state.

In CO2 lasers, the active medium is not only CO2 gas but also the Nitrogen & Helium exists there too. Here Nitrogen gas acts as a buffer gas. The nitrogen gas absorbs the pumping energy from current flow in gas and transfers this energy through collision to CO2 molecules. So the CO2 molecules reach to their excited Meta stable state. When they reach to Meta stable state and drops from this excited level then lasing occurs. In this way buffer gas is needed in CO2 gas lasers.

Application / Uses of CO2 Lasers

The CO2 laser is one of the most efficient and useful gas laser discovered up to now. Its application is as follows.

- The CO2 gas laser can be used in industry usually for welding and cutting purposes.

- The CO2 laser acts as a surgical tool in the operating room.

- In both energy and weapons research, there is good field of application of CO2 lasers.

Advantages of CO2 Laser

- In CO2 laser high power levels are obtained ranges from few watts to 15000 watts.

- The CO2 gas lasers are more versatile lasers.

- The efficiency of CO2 gas lasers (i.e. 10% or higher) is beat than He-Ne and argon lasers.

- CO2 lasers have become the workhorse of the material processing industry because of their low cost (below $100 per watt).

- In many configurations the CO2 gas lasers are available.

- In some cases its divergence is small but is not true always.

- Pulsed output can be obtained from TEA CO2 lasers, making them more efficient.

- Long sealed-off lifetime of greater than 20,000 hours.

- Wide variety of output waveform formats.

- High absorption of its output wavelengths by many materials.

- Small size per watt of output power

Disadvantages of CO2 Laser

- Divergence of CO2 lasers approximately in all cases is greater than He-Ne and Argon laser. Usually the divergence is ranges from 1 to 10 milli radians.

- Beam width varies from 3mm to 100mm.

- Some CO2 lasers have the disadvantage of a short and thick optical cavity.

- Cooling system requirement in some configurations also a disadvantage.

- Its cost is comparatively high.

- In TEA design of CO2 laser it is very difficult to maintain ionization in the gas.