Essential Laser Components

There are four essential or basic components of laser, may be listed as:

- Active medium

- Excitation mechanism

- Feedback mechanism

- Output coupler

Active medium

The active medium is the collection of atoms, ions or molecules in which the stimulated emission occurs. It can be either solid, liquid, gas or semiconductor material. For example, the Ruby laser has a crystal of ruby for its active medium while the CO2 laser has carbon dioxide gas as active medium.

The wave length emitted by a laser is a function of active medium because the atoms within the active medium have their own characteristics energy level at which they release photons.

Technically speaking, the active medium is the substance that actually laser. For example in He-Ne laser only neon gas laser.

Within the laser active medium is usually in the shape of a cylinder or is held within cylindrical container. However other geometries may also be used.

Excitation Mechanisms

The excitation mechanism is a device used to impart or put energy into the active medium.

Now the process of imparting energy to the active medium is called “PUMPING THE LASER OR ENERGY PUMPLING”. The energy pumping can be done by three types of excitation mechanism i.e.

Optical excitation

Electrical excitation

Chemical excitation

All these three mechanisms provide the necessary energy to raise the energy state of an atom, ion or molecule of active medium to an excited state.

Optical excitation

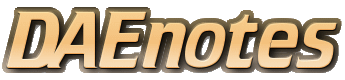

An optical excitation mechanism uses light energy (not electrical energy) of the proper wavelength to excite the active medium. That is why it is called O.E mechanism.

Here the light may comes from several sources such as flash lamp, continuous arc lam, another laser or even a sun.

Optical excitation is generally used with active medium that do not conduct electricity. So this type of excitation is used exclusively with solid lasers, for example Ruby laser.

Schematic diagram of an optically pumped laser is

Electrical excitation

An electrical excitation mechanism uses electrical energy to excite the active medium. Best electrical energy source is battery.

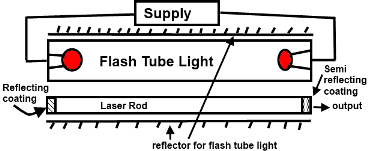

The electrical excitation is most commonly used when the active medium support an electric current. So this type of excitation is used usually with gas or semiconductor laser. For example He-Ne laser.

Schematic diagram of electrically excited laser is

When a high voltage is applied to a gas then current carrying electrons or ions move through the active medium carrying energy with them. As they collide with the atoms, ions or molecules of the active medium, then their energy is transferred and excitation occurs.

Noted that the atoms, ions and electrons within the active medium are called Plasma.

Chemical excitation

The chemical excitation mechanism uses chemical energy to excite the active medium.

For source of chemical energy certain chemicals are mixed, so due to chemical bond formation of broken, energy released. This energy can be used as a pumping source.

The chemical excitation is used in a limited number of lasers for example in hydrogen fluoride lasers, which is extremely high powered device and only used for military applications.

Feed Back Mechanisms

The mirrors are used at each end of the active medium as a feedback mechanism. These mirrors reflect the light produced in the active medium back into the medium along its longitudinal axis.

When these mirrors are aligned parallel to each other, they form the resonant cavity for the light waves produced within the laser. That is they reflect the light waves back and forth through the active medium.

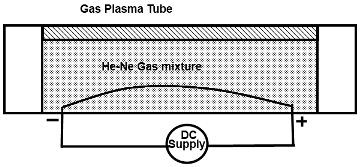

We know that light is amplified through stimulated emission. So in order to keep stimulated emission at maximum we must keep the light within the amplifying medium for the greatest possible distance. In fact the mirrors increases the distance traveled by the light through the active medium. The path that the light takes through the active medium is determined by the shape of mirrors, as shown by some possible mirror combination.

From the figure it is clear that both types of mirrors (plane and curved) are used for feedback mechanism. The curved mirrors effects the direction in which the reflected light moves.

Reflectivity from mirror is an important characteristic of laser mirrors. A mirror’s reflectivity is its ability to reflect incident light. Mirrors can be designed to reflect just about any percentage of this light. This is necessary because there are a great number of laser types available and they require different mirrors. For instance, in very low power lasers, it sometimes necessary to reflect as much as 99.99% of the laser light back into the resonant cavity in order to keep power losses at a minimum. On other hand, in high power lasers the mirrors reflectivity can be significantly less.

Remember that curvature of mirrors surface is also important. For simplicity and accuracy, the flat mirrors are used in great many lasers, especially high power solid lasers. However it is very common to use curved mirror surfaces. The type and amount of curves must be matched with the distance between the mirrors for best performance.

Output coupler

The output mirror that is designed to transmit a given percentage of the laser light in the cavity between the feedback mirrors is called the output coupler.

Since the feedback mechanism keeps all the light inside the laser cavity. Now in order to produce the output beam, a portion of the light in the cavity must be allowed to escape by the help of output coupler. This escape must commonly controlled by using a partially reflective mirror in the feedback mechanism. The amount of reflectance required varies with the type of laser. High power lasers may use as little as 35% reflectance with the remaining 65% being transmitted through the mirror (output coupler) to become the output laser beam. A low power laser may require an output mirror reflectivity as high as 98% leaving only 2% to be emitted.

Something general about mirrors

The mirror layers or covering is called the mirror coating. A mirror is a made of a mirror blank or mirror substrate and a reflective coating. The mirror substrate is the material onto which the reflective coating is applied. This material is usually glass, quartz or metal.

The reflective coating is a thin film coating that is applied to substrate. This film can be applied in either single or multiple layers.

The coating materials will increase the reflectance of mirror over a specific range of wavelengths.

Metal films are the oldest form of reflective coating therefore nowadays new form called dielectric coating is used. This becomes most popular for use in laser applications due to following reasons.

- To improve the reflectance of mirror surface.

- To control the reflectance, thus allowing a fixed percentage of light to be transmitted by the mirror.

- To reduce the reflection of unwanted wavelengths.