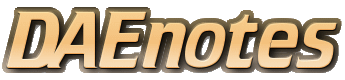

Gate turn OFF (G.T.O) Thyristor

The conventional thyristor can only be turned off by effectively reducing the anode current to zero, but the gate turn-off thyristor, as its name implies, has a structure such that it can be turned off y removing current from the gate. While the turn-on is achieved by injecting current into the gate as in the conventional thyristor.

The gate turn-off thyristor has highly doped N spots in the P-layer at the anode, the plus sign indicating high doping levels. The gate cathode structure is interdigitated that is each electrode is composed of narrow channels closely located.

Turn ON Condition for G.T.O Thyristor

The turn-on conditions for the gate turn-off thyristor are similar to the conventional thyristor, but because of the different structure, the latching current is higher. The interdigitated nature of the gate results in a very rapid spread of conduction in the silicon, but it is necessary to maintain the gate current at a high level for a longer time to ensure that latching takes place.

Turn OFF Condition for G.T.O Thyristor

The thyristor remains ON after the removal of the gate current because the internal mechanism of carrier multiplication is self-maintaining provided the anode current is above the latching level.

With the gate off thyristor, it is possible to cause the carrier multiplication to cease by removing holes from the p-region, which causes the conduction area to be squeezed towards the anode N spots into the area under the cathode electrode furthest from the gate electrode, until all the conducting paths are extinguished.

Once the cathode current has ceased a gate anode current persists for a short time until the device gains its blocking state. The magnitude of the gate current for turn-off is of the order of one-fifth to one-third of the anode current, hence it is considerably higher than the turn-on magnitude. The time of turn off is shorter than with the other thyristors.

Gating Requirements for G.T.O Thyristor

At turn-on, a current is injected into the gate. At turn-off a negative voltage is placed across the gate cathode of the order of 10V, thus removing current from the gate. The turn-off voltage must be less than the gate cathode reverse breakdown but high enough to extract the charge necessary to bring about turn-off.

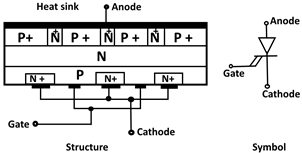

Use of Snubber Capacitor C

To limit the rate at which anode voltage rises at turn-off, a Snubber capacitor is connected across the thyristor.

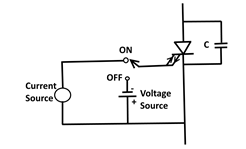

Simple Practical Gate Control Circuit

Operation:

Positive current to the base of transistor T1 (NPN) allows current flow into the gate via R1 & C1 with the initial value being set by R1. The zener diode D1 conducts when its breakdown voltage is reached, thus holding the charge on capacitor C1 (say) 12V, allowing a small continuous gate current to flow from the 15V supply as ideally required.

Reversal of the control current will turn transistor T2 (PNP) ON, T1 going OFF. With T2 ON, the capacitor C1 discharges via T2, removing the gate current & turning the thyristor OFF.

Use of Snubber Capacitor C2

The Capacitor C2 across the thyristor limits the dv/dt rise of the anode-cathode voltage.

Comparison between Conventional and G.T.O Thyristor

There are a number of differences between conventional & G.T.O thyristors.

- Conventional thyristors can only be turned off by effectively reducing the anode current to zero. But the G.T.O. thyristor can be turned off by applying a negative pulse at the gate.

- The structure of both devices is different

Figure - Symbols of both devices are different

Figure - The gate-Cathode structure of the G.T.O thyristor is interdigitated but that of the conventional thyristor is not.

- Reverse blocking capability is relatively less for G.T.O. thyristors as compared to that of conventional thyristors.

- The time of turn-off for a G.T.O. thyristor is small as compared to a conventional thyristor.