Losses and Power Stages In Induction Motor

Losses In Induction Motor

There are three main types losses in induction motor:

- Copper losses

- Iron losses

- Friction and windage losses

Copper Losses

The copper losses occur in stator and rotor windings. This type of loss depends upon the current in the winding. This loss is also called electrical or "12R" loss. The winding resistance is found by calculating the wire size and length. Multiplying this resistance by the square of the current, copper losses are determined.

Iron Losses

This type of losses occurs in the stator and rotor cores of induction motor. This type of loss is also called core or magnetic loss. This loss consists of hysteresis and eddy current loss. Both these losses depend on supply frequency and on flux density in the core. This loss is practically constant for the stator iron core and negligible for the rotor iron core. Because frequency of stator current is constant while under normal running condition, frequency of rotor current is very small.

Friction and Windage Losses

These losses are due to the friction of the moving parts and due to the wind resistance. These losses are also called mechanical losses.

Power Stages in an Induction Motor

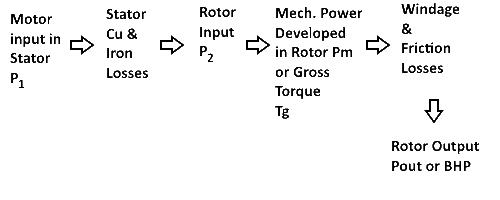

Power stages diagram showing the power losses in a different part of the machine. See Figure 1.

Figure 1: Power Stages and Losses Diagram of 3 Phase Induction Motor

The different stages of this diagram are discussed as follows:

- Motor input or stator input = stator output + stator losses

- Rotor input = stator output

Rotor gross output

Developed in rotor, Pm = Rotor input - rotor cu.loss

Gross Torque developed, Tg = Rotor gross output / 2πN --- (1)

If there were no Cu. Losses in the rotor, then rotor output will be equal to rotor input and the rotor will run at synchronous speed:Tg = Rotor input / 2πNs --- (2)

From equation (1) Rotor output = Tg 2πN --- (3)

From equation (2) Rotor input = Tg x 2 ΔNs --- (4)As copper losses = Rotor input - Rotor output.

So Rotor Cu.losses= Tg2π(Ns – N) --- (5)

From equation (4) & (5)

Rotor Cu. Loss / Rotor Input = (Ns – N )/ Ns

Or

Rotor Cu. Loss = S x Rotor input --- (6)

And Rotor gross output = Rotor input - Rotor Cu. Loss --- (7)

Rotor gross output = (1-S) Rotor input

Rotor efficiency = Rotor gross output / Rotor Input

= (1 - S) Rotor Input / Rotor Input = 1-S

Rotor efficiency = 1-S = 1 - (Ns-N)/Ns = N / Ns

= actual speed of rotor / Synchronous speed

Note for 3-phases rotor Cu. Losses = 3I22R2

Motor output = Mechanical power developed in rotor, Pm windage and Friction losses.

If motor out put is in B.H.P.

Motor output = B.H.P. x 746 Watts

Efficiency of motor = output / Input = ((B. H. P. x 746) / Stator input) x 100

EXAMPLE 1:

The rotor e.m.f. of a 3-phase, 6-pole, 400-V, 50Hz, induction motor alternates at 3Hz. Compute the speed and percentage slip of the motor. Find the rotor copper loss per phase if the full input to the rotor is 111.9 KW.

SOLUTION:

S = fr / f = 3/50 = 0.06 or 6%

Ns = 120x50 / 6 = 1000 r.p.m.

N = (1-S) Ns = (1 - 0.06) 1000 = 940 r.p.m.

Rotor input = 111.9 kW = 111900W

Rotor Cu. Loss = S x rotor input = 0.06 x 111900 = 6715W

Rotor Cu. Loss per phase = 6715 / 3 = 2238W

EXAMPLE 2:

A 400-V, 50 h-p, 3-phase induction motor is drawing 50A at 0.8 P.f. The losses in the motor are:

- stator cu. Loss = 1800W

- rotor cu. Loss = 800W

- friction loss = 500W

- rotational and core loss 1750W

Complete

- the rotor power input

- the mechanical power developed

- the output powers

- efficiency of the motor

Stator input= √3 VI CosØ

= √3 x 400 x 50 x 0.8 = 27712.8W

- Rotor input = stator input - Stator cu. Loss

= 27712.8 - 1800

= 25912.8W - Mechanical power developed = rotor input - rotor cu. Loss

= 25912.8 - 800

= 25112.8W - The output power = Mechanical power develop

Iron and friction losses

= 25112.8 - (500 + 1750)

= 22862.8W = 30.6 h.p. - Efficiency, η = (22862.8 / 27712.8) x 100 = 82.5%