Causes of Light Losses in Fiber Optics

Fiber optics technology has revolutionized modern communication and data transmission by enabling the transfer of information at lightning-fast speeds over long distances. However, even this advanced technology isn't immune to light losses, which can have detrimental effects on signal quality and efficiency. In this article, we delve into the causes of light losses in fiber optics, shedding light on the factors that contribute to this phenomenon.

Fiber Optics: A Brief Overview

Fiber optics involves the transmission of data through thin strands of glass or plastic, known as optical fibers. These fibers guide light pulses, or photons, that carry data over long distances using the principle of total internal reflection. The efficiency of this process is crucial for maintaining signal integrity and preventing light losses.

Causes of Light Losses

Several factors can lead to light losses in fiber optics, impeding the seamless transmission of data. Let's explore these factors in detail:

Attenuation

Attenuation refers to the reduction in signal strength as light travels through the fiber. This can occur due to the absorption, scattering, and bending of light within the fiber. Absorption occurs when the fiber's material absorbs some of the light energy, converting it into heat. Scattering results from interactions between light and impurities or imperfections in the fiber, causing the light to change direction. Bending the fiber beyond its critical angle can also lead to signal loss.

Dispersion

Dispersion occurs when different wavelengths of light travel at different speeds within the fiber, causing a spreading or smearing of the light pulse. Chromatic dispersion and modal dispersion are the primary types of dispersion. Chromatic dispersion stems from variations in the refractive index for different wavelengths, while modal dispersion arises from differences in propagation paths for various light modes.

Connectors and Splices

Imperfect connectors and splices can introduce losses by causing reflections or misalignments in the optical path. These issues lead to a portion of the light being scattered or lost at the connection points, reducing overall signal strength.

Bending Losses

Excessive bending of optical fibers can result in micro bends and macro bends, both of which contribute to signal loss. Microbends are tiny imperfections in the fiber's core or cladding, while macrobends are larger bends that cause light leakage. Proper handling and installation of fibers are crucial to mitigate bending losses.

Material Loss

The loss caused by the material and its impurities rather than by structural defects in fiber is called material loss also known as absorption loss sometimes.

The best example of material loss is the absorption of light by material, due to light interacting with the molecular structure of the material.

The loss due to the atomic structure of the material itself is relatively small. For example, in germanium Silicon glass this loss is less than 0.1 dB/km with λ between 0.8 -> 1.6 µm. at λ ≅ 1.3µm, the loss is nearly zero.

The loss due to impurities can be reduced by a better manufacturing process. In improved fibers, the internal impurities are practically negligible.

The largest loss is caused by OH-ions and these cannot be sufficiently reduced. Because the OH impurity causes loss for particular wavelength bands, the worst loss (about 4 dB/km) occurs near λ = 1.4µm for an impurity concentration of 1ppm.

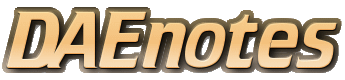

The OH absorption peaks for concentrations larger than 1ppm can be shown as:

The loss peaks occur at points of wavelengths. i.e,

0.93 µm 1st one

1.25µm 2nd one

1.40µm 3rd one

Light Scattering

The reflection of light in many directions is called light scattering. The scattered light does not propagate down the fiber but it is lost.

Light can be scattered by molecules of the material by structural imperfections and impurities.

Typically light scattering is caused by an obstruction. So when an obstruction scatters the light then the result is power loss. The term obstruction refers to the density variations in the material that result in changes in the refractive index.

There are two types of scattering. i.e. scattering by small obstruction & large obstruction.

Scattering by Small Obstructions

In this type when the index variations are molecular in size, then power loss is due to Rayleigh scattering. These small obstructions, which are inherent in the manufacturing process and cannot be eliminated because it behaves like point sources, scattering light in all directions. The Rayleigh scattering loss greatly depends on wavelengths. It varies as 1 / λ4, which means that due to longer wavelengths, the power loss is lower. The effects of Rayleigh scattering losses are shown in Figure 1 above.

Scattering by Large Obstructions

By large obstructions, macrobands, or fiber deformation the light can be scattered. But this type of loss is minimized by well-improved manufacturing techniques.

By figure, we can show this type of scattering as:

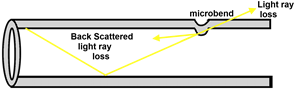

Waveguide & Microbend Losses

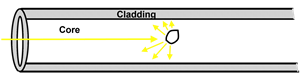

The waveguide or optical waveguide is the name of optical fiber. The structure variations in the fiber or fiber deformation cause the radiation of light away from the fiber and so power is lost.

A change in the diameter of fiber also causes the radiation loss shown as:

Here in the figure, the angle α1 is smaller than the critical angle so that is why that ray leaves the fiber. In the absence of the deformation, the ray would be confined to the fiber as shown by the dashed line (blue color).

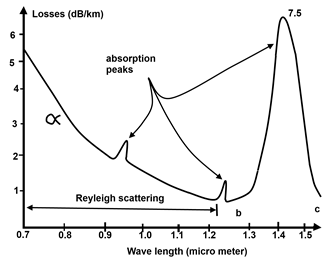

The micro bend is the very minute disturbance in core size. It also causes radiation of light, as shown in the figure:

So losses caused by imperfection and deformation of fiber structure are called bend losses.

Thus any variations in refractive index along the fiber will cause a similar energy loss. However in most cases the loss results from the scattering of light.

Conclusion

Understanding the causes of light losses in fiber optics is essential for optimizing signal quality and maintaining efficient data transmission. Attenuation, dispersion, imperfect connectors, bending losses, and material impurities are the primary culprits behind light losses. As technology advances, addressing these factors through improved materials, precise manufacturing, and meticulous installation will play a pivotal role in enhancing the performance of fiber optic systems. By overcoming these challenges, we can pave the way for even faster and more reliable communication networks in the future.